NNSA/ U.S. Department of Energy

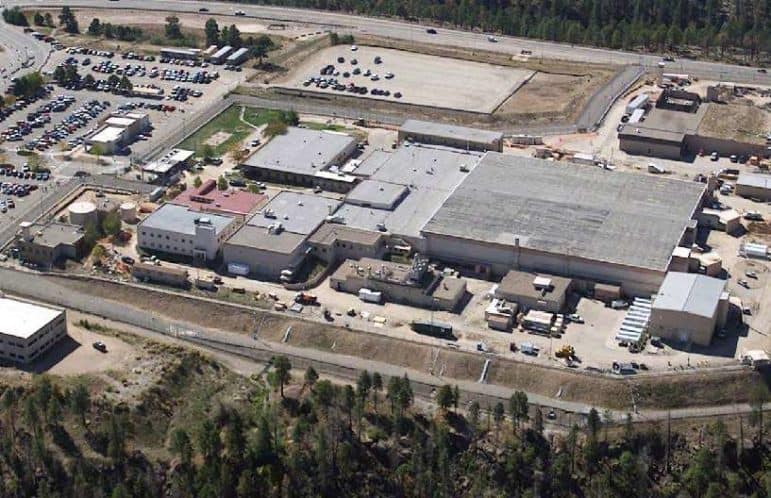

Plutonium Facility-4 at Los Alamos National Laboratory houses plutonium operations vital to the lab’s national security mission, but work there has been mostly paused since June 2013.

In mid-2013, four federal nuclear safety experts brought an alarming message to the top official in charge of America’s warhead production: Los Alamos National Laboratory, the nation’s sole site for making and testing a key nuclear bomb part, wasn’t taking needed safety precautions. The lab, they said, was ill-prepared to prevent an accident that could kill lab workers, and potentially others nearby.

Some safety infractions had already occurred at the lab that year. But Neile Miller, who was then the acting head of the National Nuclear Security Administration in Washington, says those experts specifically told her that Los Alamos didn’t have enough personnel who knew how to handle plutonium so it didn’t accidentally go “critical” and start an uncontrolled chain reaction.

Such chain reactions generate intense bursts of deadly radiation, and over the last half-century have claimed nearly two dozen lives. The precise consequences, Miller said in a recent interview, “did not need an explanation. You don’t want an accident involving criticality and plutonium.” Indeed, Miller said, criticality “is one of those trigger words” that immediately gets the attention of those responsible for preventing a nuclear weapons disaster.

With two of the four experts remaining in her Washington office overlooking the national mall, Miller picked up the phone and called the lab’s director, Charles McMillan, at his own office on the idyllic Los Alamos campus in the New Mexico mountains, where nuclear weapons work is financed by a federal payment exceeding $2 billion a year. She recommended that a sensitive facility conducting plutonium operations — inside a building known as PF-4 — be shut down, immediately, while the safety deficiencies were fixed.

McMillan, a nuclear physicist and weapons designer with government-funded compensation exceeding a million dollars a year, responded that he had believed the problems could be solved while that lab kept operating. He was “reluctant” to shut it down, Miller recalled. But as the call proceeded, he became open to her view that the risks were too high, she added. So on McMillan’s order, the facility was shut within a day, with little public notice.

In the secrecy-shrouded world of America’s nuclear weapons work, that decision had far-reaching consequences. Shuttering a key part of PF-4 abruptly halted two types of sensitive work done nowhere else in the United States, for roughly the next four years: The invasive sampling and analysis of selected aging nuclear weapons cores to ensure that intact models could all still function as intended; and the production of new cores that could be fit into more modern nuclear weapons or replace those pulled apart in testing.

The shutdown was not expected to last nearly so long, but Los Alamos’s managers have struggled for years to meet basic safety standards and had difficulty getting the lab back to full operations. The exact cost to taxpayers is unclear, but internally Los Alamos estimated in 2013 that idling the facility where such work is conducted costs more than a million dollars a day in lost productivity alone.

And these safety challenges aren’t confined to Los Alamos. The Center’s probe revealed worker safety risks, previously unpublicized accidents, and dangerously lax management practices at other nuclear weapons-related facilities. The investigation further found that penalties for these practices were relatively light, and that many of the firms that run these facilities were awarded tens of millions of dollars in profits in the same years that major safety lapses occurred. Some were awarded new contracts despite repeated, avoidable accidents, including some that exposed workers to radiation.

But the consequences also extend to America’s overall national security. The years-long halt in the invasive testing of plutonium cores, or “pits” as they are also known, means that between 2013 and this year, the United States has not been able to examine in detail how well or poorly the cores of the most critical warheads in its arsenal have been aging. Among them: warheads carried by America’s nuclear submarines and land-based intercontinental ballistic missiles, plus an older type of warhead still stockpiled for use by strategic bombers.

The government has generally not publicized how disruptive the hiatus at Los Alamos has been, although telltale data appear in obscure reports by the National Nuclear Security Administration. They reveal that nuclear weapons scientists had planned to check 29 plutonium cores with invasive testing at Los Alamos over the past four years. But that schedule had to be scrapped, and it was not until the second half of 2016 that the lab scheduled two such tests. One failed and the other was cancelled due to poor safety preparations.

Ordinarily, new warhead pits are produced steadily by technicians at PF-4 for installation in modernized weapons, to replace some of those pits withdrawn for testing, and to keep workers there trained and agile. But Los Alamos has not fabricated any new plutonium cores for existing or modernized warheads since 2011. And restarting that work safely is not the only challenge: Last July, an internal NNSA report said this core fabrication work will likely cost the government at least an extra $100 million over the next four years beyond the funds already set aside for such work, due to rising equipment costs.

“The laboratory shut down an important facility doing important work,” said James McConnell, the NNSA’s associate administrator for safety, infrastructure, and operations, in a recent interview at the agency’s Washington headquarters. “What we didn’t have was the quality program that we want.”

Key lab remains only partly active

Los Alamos and the NNSA have publicly boasted that PF-4 has recently been fully restarted, but in truth, it’s only accomplished exercises and dry runs of its most important missions.

The little-known hiatus has forced the directors of the three principal U.S. weapons laboratories to rely on other types of reliability tests, mostly conducted at other U.S. nuclear weapons facilities, when they promised in annual reports to the President and the Congress that the country’s warheads will still explode in the manner intended by their designers. The highly classified reports, known as ROSAs, for Report on Stockpile Assessment, did not highlight the pit testing interruption, according to two people who have read them.

Through Los Alamos spokesman Kevin Roark, McMillan declined CPI’s request to be interviewed, and the laboratory did not respond to questions about his conversation with Miller, the lab’s safety record, or the consequences of the shutdown. But that interruption of Los Alamos’s pit production and testing — the latter of which is meant to substitute in part for full-scale explosive nuclear testing — has made some of those responsible for managing the nuclear stockpile uncomfortable.

“We were obviously quite concerned about” the shutdown at Los Alamos, recalled Ernest Moniz, the MIT physicist who was President Obama’s Secretary of Energy from May 2013 to January 2017, in an interview with the Center. Moniz said he considered the situation there a “mess” and the invasive testing interruption “significant.” The shutdown blocked, he said, the planned production of some new cores for nuclear warheads. He and Frank Klotz, the NNSA director, took a special trip to the lab in in 2014 to emphasize that restarting its work was “a very high priority,” Moniz added.

Klotz declined to be interviewed but in a statement issued on June 19, in response to an article the Center published that day, said Los Alamos had “demonstrated improvements in its performance of operational tasks” and had worked to minimize the impact of the pause on “the safety and reliability of the nuclear weapons stockpile.” He also said the NNSA had held Los Alamos “accountable for these issues.”

But Richard Garwin, a retired IBM physicist and Presidential Medal of Freedom recipient who has long been a technical adviser on nuclear weapons and stockpile surveillance to the Defense Department and the NNSA, said the government had not been transparent enough about the long lapse in testing and production. He echoed Moniz in asserting that the existing plutonium cores — built to trigger a release of energy that in turn powers a thermonuclear explosion of immense destructive power — will still function, because they are extremely durable.

But Garwin said “it’s extremely embarrassing” for the lab to be unable to carry out its planned tests. “How could they screw up so badly? We’re not getting our money’s worth out of the people at Los Alamos.”

A unique task, unfulfilled for the past four years

Before the work was halted in 2013, those overseeing the U.S. nuclear arsenal typically pulled six or seven warheads from bombers or missiles every year for dismantlement and invasive diagnostic testing. One reason is that the unstable metals that act as spark plugs for the bombs — plutonium and highly-enriched uranium — bathe themselves and nearby electrical components in radiation, with sometimes unpredictable consequences; another is that all the bombs’ metallic components are subject to normal, sometimes fitful corrosion.

Plutonium also slowly decays, with some of its isotopes becoming uranium. And the special high explosives fabricated by nuclear scientists to compress the plutonium cores in a deliberate detonation also have an unstable molecular structure.

Invasive testing provides details vital to the computer modeling and scientifically simulated plutonium behavior that has replaced nuclear testing, said DOE consultant David Overskei. He compared the pit — so named because it is spherical and positioned near the center of a warhead — to the heart of a human being, explaining that destructive testing is like taking a blood sample capable of exposing harmful maladies.

The aim, as Vice President Joe Biden said in a 2010 National Defense University speech, has been to “anticipate potential problems and reduce their impact on our arsenal.” Weapons designers say it’s what anyone would do if they were storing a car for years while still expecting the engine to start and the vehicle to speed down the road at the sudden turn of a key.

Typically, warheads selected for testing are first sent to the Energy Department’s Pantex Plant in Amarillo, Texas. Technicians there gently separate their components — such as the detonators — at that site; they also send the pits — used in a primary nuclear explosion — to Los Alamos, and the highly-enriched uranium — used in a secondary explosion — to Oak Ridge, Tenn. The arming, fusing and firing mechanisms are tested by Sandia National Laboratories in Albuquerque and other locations.

At Los Alamos, the pits are brought to Plutonium Facility-4 (PF-4), a boxy, two-story, concrete building with a footprint the size of two city blocks. Inside are hundreds of special “glove boxes” for working with plutonium, a series of individual laboratories, and a special vault, in which containers hold plutonium on racks meant to ensure that escaping neutrons don’t collide too often with other atoms, provoking them to fission uncontrollably. Only a small portion of the building is normally used for pit surveillance, while about a fifth is used for pit fabrication, and another seven percent for analytical chemistry and pit certification. Budget documents indicate that annual federal spending for the work centered there is nearly $200 million.

“The Los Alamos Plutonium Facility is a unique and essential national security capability,” McMillan, the lab’s director, said last September during a visit by then-Defense Secretary Ashton Carter, who watched as technicians — attempting to restart their work after the lengthy hiatus — used pressing machines and other equipment to fabricate a mock pit, rather than a usable one.

The building lies in the middle of a 40-acre campus in the mountains above Santa Fe hastily built during World War II to coordinate the construction of the two nuclear bombs used in Japan. Los Alamos is still considered the foremost U.S. nuclear weapons facility — where six of the nine warheads currently in the U.S. arsenal were designed, and where plutonium-based power supplies for most of the nation’s deep-space probes are fabricated. Hundreds of nuclear physicists work there.

Unfortunately, it also has an active seismic zone beneath the PF-4 building, producing persistent worries among the staff and members of the Defense Nuclear Facilities Safety Board, a congressionally-chartered oversight group, that if it experienced a rare, large earthquake, the roof could collapse and toss chunks of plutonium so closely together a chain reaction would ensue, spewing radioactive, cancer-causing plutonium particles throughout nearby residential communities.

Millions of dollars have already been spent to diminish this risk, which until recently exceeded federal guidelines, and the Trump administration last month proposed spending $14 million in 2018 alone to strengthen the building’s firewalls and sprinkler systems. The government has also sunk more than $450 million into preparations for construction of a modern and more seismically durable pit production facility at Los Alamos, projected to have a total price tag between $1.5 billion and $3 billion.

Making new pits involves melting, casting and machining the plutonium, while assessing how well or poorly the pits are aging requires using various instruments to withdraw small pieces for detailed chemical and material analysis. These operations are typically done in the glove boxes, by specialists whose hands are inserted into gloves attached to the side of sealed containers meant to keep the plutonium particles from escaping. But the work is messy, requiring constant vigilance to be certain that too much of the metal doesn’t pile up in a compact space. The byproducts include “chunks, shards, and grains of plutonium metal,” all of it radioactive and unstable, according to a 2015 Congressional Research Service report.

Notably, a 2013 Los Alamos study depicted leaks of glove boxes at PF-4 as frequent — averaging nearly three a month — and said they were often caused by avoidable errors such as inattention, improper maintenance, collisions with rolling storage carts, complacency and degradation from the heat that plutonium constantly emits. It said that sometimes those operating or supervising the equipment “accepted risk” or took a chance, rushed to meet a deadline, or otherwise succumbed to workplace production pressures.

“Operations always wants it yesterday,” the lab’s current criticality safety chief and the lone NNSA expert assigned to that issue in the agency’s Los Alamos oversight office warned in a private briefing for their colleagues at Sandia labs last month. Managers “must shield analysts from demands” from production personnel, they said.

Besides posing a serious health risk to those in PF-4, glove box releases of radioactive material each cost the government $23,000 to clean up, on average, the Los Alamos study said.

An acute shortage of criticality experts

Calculating exactly “how much material can come together before there’s an explosion” — as the Nobel laureate physicist Richard Feynman once put it — is a complex task. While visiting the production site for highly-enriched uranium in Oak Ridge, Tenn., during the 1940s, for example, Feynman was surprised to see stocks of that fissionable material deliberately stored in separate rooms, but on an adjoining wall that posed no barrier to collisions involving atoms of uranium and escaping neutrons on both sides. “It was very dangerous and they had not paid any attention to the safety at all,” Feynman wrote years later.

Plutonium work is so fraught with risk that the total mass of that metal allowed to be present in PF-4 is strictly limited. A decade ago, the limit was increased without an appropriate understanding of the risks, according to an NNSA technical bulletin in February. But with pieces of it strewn and stored throughout the normally busy building, partly because the vault is typically full, its managers have labored for years to systematically track down and remove excess stocks. They had some success last year, when they got rid of nearly a quarter of the plutonium on the building’s “main floor,” according to recent budget documents.

Criticality specialists are employed not only to help set these overall mass limits but to guide technicians so they don’t inadvertently trigger chain reactions in their daily work; those specialists are also supposed to be the first-responders when too much dangerous material is found in one place.

“The weird thing about criticality safety is that it’s not intuitive,” Don Nichols, a former chief for defense nuclear safety at the NNSA, said in an interview. He cited an instance in which someone operating a stirring machine noticed that fissionable liquids were forming a “critical” mass, so the operator shut the stirrer off, not immediately realizing that doing so made the problem worse. In other instances, analysts had judged a plutonium operation was safe, but then more workers — whose bodies reflect and slow neutrons — wound up being present nearby, creating unanticipated risks.

Those doing the weapons disassemblies and invasive pit studies are typically under “a big level pressure” to complete a certain number every year, Nichols added. They are expected to do “so many of these in this amount of time,” to allow the labs to certify to the president that the stockpile is viable. Meanwhile, the calculations involved in avoiding criticality — which depend on the shape, size, form, quantity and geometric configuration of material being used in more than a dozen different industrial operations — are so complex that it takes a year and a half of training for an engineer to become qualified and as many as five years to become proficient, experts say.

“It’s difficult to find people who want to do this job,” particularly at the remote Los Alamos site, said McConnell, the NNSA safety chief. With plutonium use mostly confined to creating the world’s most powerful explosives, “there are… very few public-sector opportunities for people to develop these skills,” he added. As a result, he said, many NNSA sites lack the desired number of experts, which slows down production.

At the time of the 2013 shutdown, after numerous internal warnings about the consequences of its mismanagement, Los Alamos had only “a single junior qualified criticality safety engineer” still in place, according to the February NNSA technical bulletin. Nichols, who was then the NNSA’s associate administrator for safety and health, said McMillan didn’t “realize how serious it was until we took notice and helped him take notice.”

Without having adequate staff on hand to guide their operations safely, technicians at PF-4 were unable to carry out a scheduled destructive surveillance in 2014 of a refurbished plutonium pit meant for a warhead to be fit atop American submarine-launched ballistic missiles. It’s been modernized at a cost of $946 million since 2014, with total expenses predicted to exceed $3.7 billion. Generally, up to 10 of the first pits produced for a new warhead type are set aside for surveillance to assure they’re safely constructed and potent before they’re deployed. But the planned disassembly was cancelled and the NNSA hasn’t scheduled another yet, because of the shutdown.

The lab also hasn’t been able to complete planned invasive studies of the aging of plutonium used in a warhead for an aircraft-delivered nuclear bomb, now being modernized at an estimated cost of $7.4 billion to $10 billion.

Former deputy NNSA director Madelyn Creedon told an industry conference in March that if new funds are given to the agency in President Trump’s new budget, she knows where she’d advise it be spent. “One of the things that doesn’t take a huge amount of money but it’s one that has been cut back over the last couple of years, is surveillance — enhanced surveillance” of existing warheads, Creedon said.

The shortcomings persist

Los Alamos’ progress in improving its criticality safety since the shutdown began has been fitful, and the dissonance between safety experts and its top managers has stubbornly persisted.

McMillan initially promised to train fissile material handlers to be more heedful of plutonium-handling perils, for example, and to bring the inventory and safety documents guiding their work up to date. In an email to lab employees, he promised that a “pause” lasting less than a year wouldn’t cause “any significant impact to mission deliverables.”

But at the end of 2013, a new group of safety experts, commissioned by the lab to guide its reforms, delivered bad news just as the lab was attempting to restart operations at PF-4. “Management has not yet fully embraced its commitment to criticality safety,” the group said, according to a copy of its report obtained by CPI.

It also listed nine weaknesses in the lab’s safety culture that were rooted in a “production focus” to meet work deadlines. Workers say these deadlines are typically linked to financial bonuses. Los Alamos’ leaders, the report said, had made the right promises, but failed to alter the underlying safety culture. “The focus appears to remain short-term and compliance oriented rather than based on a strategic plan,” the report said.

In May 2014, Peter Winokur, who at the time chaired the Defense Nuclear Facilities Safety Board, weighed in with a separate, written warning to the head of the National Nuclear Security Administration. He said McMillan was improperly trying to restart “high-risk” PF-4 operations without first carefully setting new, written, safety benchmarks for the lab’s plutonium work.

The NNSA head, Klotz, alerted the Secretary of Energy, Moniz, and the two of them flew to Los Alamos to meet with McMillan, a man known for both charm and hubris. “Los Alamos is a legend,” McMillan has boasted in a promotional video. “It’s an icon. And of course, because of that, everybody notices what we do here; and we’re held to a very high standard.”

Moniz said he told McMillan personally that “I was not entirely satisfied with the reactions of some of his senior managers.” As a result, he said, “actions were taken,” without offering details.

But progress was not swift.

The NNSA, in its annual evaluation of Los Alamos’ overall performance for fiscal year 2014, judged the criticality safety program to be “below expectations” with deficiencies “similar to issues identified in past” evaluations; it particularly faulted the labels the lab had placed on nuclear materials and the guides the lab had prepared for workers performing plutonium handling chores.

Some of these shortfalls persisted in 2015, and new ones were discovered. On May 6, 2015, for example, the NNSA sent Los Alamos’ managing contractors a letter again criticizing the lab for being slow to fix criticality risks. The Defense Nuclear Facilities Safety Board, which summarized the letter in one of its weekly reports, said “there are currently more than 60 unresolved infractions,” many present for months “or even years.”

In January and again in April 2015, workers discovered tubes of liquids containing plutonium in seldom-used rooms at PF-4, with labels that made it hard to know how much plutonium they held or where they’d come from, the safety board said. In May, workers packed a drum of nuclear waste with too much plutonium, posing a criticality risk, and in the ensuing probe, it became clear that they were relying on inaccurate and confusing documentation. Safety experts had miscalculated how much plutonium the drum could safely hold.

“These issues are very similar to the issues that contributed to the LANL Director’s decision to pause operations in June of 2013,” safety board inspectors wrote.

Asked about the persistence of the Los Alamos lab’s problems, former NNSA director Miller smiled and said her colleagues at the nuclear oversight agency sometimes told the following joke: If Washington sent all three of America’s nuclear weapons labs an order to study how to “jump,” they would all respond differently. Lawrence Livermore, she said, would convene a conference and produce a three-inch stack of reports about “jumping.” Officials at Sandia would simply jump.

But at Los Alamos, she said, officials would instinctively respond with a “**ck you, we’re not jumping.”

New troubles last year

In 2016, for the third straight year, the Energy Department and the Defense Nuclear Facilities Safety Board each listed criticality safety at Los Alamos as one of the most pressing problems facing the nuclear weapons program, in their annual reports to Congress. Even now, “required improvements to the Criticality Safety program are moving at an unacceptably slow pace,” the most recent NNSA performance evaluation of Los Alamos, released in Nov. 2016, said.

Hazardous operations at PF-4 slowly started to resume during 2016, but problems continued. During a drill simulating a criticality accident on June, 15, 2016, some alarms at PF-4 didn’t work, and workers showed “inattentiveness” to a colleague who pretended to be wounded, according to a Defense Nuclear Facilities Safety Board summary of the exercise; as a result, they were judged to have failed portions of the test.

Then on June 21, 2016, after technicians working in a glove box spilled about 7 tablespoons of a liquid containing plutonium, workers violated safety rules by sopping up the spill with organic cheesecloth and throwing it in waste bins with other nuclear materials, according to an internal Los Alamos report.

Using cheesecloth in such cleanups has been barred by the Energy Department since 1994, because its contact with plutonium readily triggers chemical reactions and fires. The prohibition was ignored to ill effect on Aug. 11, 2003, when two workers at PF-4 inhaled plutonium after a sudden reaction between that material, organic cheesecloth, and acid. A similar chemical reaction stemming from the sloppy disposal of Los Alamos’ nuclear waste in 2014 provoked the shutdown of a deep-underground storage site in New Mexico for more than two years, a DOE accident investigation concluded. That incident cost the government more than a billion dollars in cleanup and other expenses.

Nonetheless, in 2016 the contractors that run Los Alamos — Bechtel National, Inc., AECOM, BWXT Government Group, Inc., and the University of California — received 74 percent or $10.7 million of the $14.4 million in profits available to them from the NNSA in the category that includes pit production and surveillance (all their actual expenses are separately reimbursed every year by the government).

In its November 2016 evaluation, which was informed in part by the contractors’ assessment of their own performance, the NNSA explained the payout. “The Laboratory exceeded expectations” in its progress toward being ready to fully resume activities in PF-4, the evaluation said. Spokesmen for the companies, as well as their joint consortium, declined comment.

Marvin Adams, a nuclear physicist at Texas A&M who has been a consultant to Los Alamos’ work with warhead pits, said that “If they continue on their path to get everything back up and running, I am pretty comfortable.” But he added that he would worry if a safety shutdown was again required. “Starting and stopping in this business is a huge issue,” Adams said. “You cannot fire these people and then go out on the street and hire them or replace them.”

But criticality experts remain worried.

One of those who went to see Miller, the NNSA director, in 2011 to complain about criticality safety was Jerry McKamy, a former NNSA nuclear physicist who is now a senior expert at the Defense Nuclear Facilities Safety Board. He declined to be interviewed for this article, but made clear in a trade journal article last December that the nuclear complex’s poor handling of criticality safety has been endemic.

Citing the safety history at Los Alamos and other facilities, McKamy wrote that “DOE and its contractors have repeatedly shown they are not capable of anticipating and preventing serious criticality safety problems.” They have persistently ignored “written and credible warnings by criticality safety and management experts,” he wrote.

Klotz, the NNSA director, has tried to be upbeat. In March, he told hundreds of nuclear contractors packed into a Washington hotel ballroom for an industry gathering that PF-4 was fully back in business, having “safely resumed all plutonium activities there after a three-year pause.”

He emphasized that Los Alamos had “assembled a production development pit” and said that work on a particular modernized warhead — due for delivery to the Navy in less than two years — provided proof of “the NNSA’s ability and the ability of our M&O partners” — contractors — to deliver updated nuclear weapons “on time and on budget.”

But a subsequent analysis by the Government Accountability Office clashed with Klotz’s description. In an April report on costs associated with the NNSA’s ongoing nuclear weapon modernization campaign, the GAO disclosed the existence of an internal NNSA report forecasting that PF-4 will be unable to meet a congressional demand for production of 30 new pits per year by 2026, as part of a 30-year, $1 trillion nuclear weapons update. It said the pit production schedule is likely to slip two to three years.

The “production development pit” Klotz referenced during his March 1 speech and publicized in photos released by NNSA was actually made during a practice run, and so it could not be used in the arsenal, according to current and former government officials with access to classified information about the work.

After Carter donned a protective moon-suit to witness the event, he issued a statement saying that “a strong plutonium science and manufacturing capability is essential to the U.S. nuclear deterrent and cannot be underestimated.” But he declined through a spokesman to say exactly what he was told by the lab during his visit about the status of the production effort.

Moreover, late last year, when Los Alamos conducted its first scheduled destructive test of a plutonium pit since the shutdown of PF-4 more than three years ago, it did not produce the needed results, according to NNSA’s annual evaluation of Los Alamos’ performance last year. The test involved the core of a refurbished warhead scheduled to be delivered to the Navy by the end of 2019 for use atop the Trident missiles carried by U.S. submarines.

It “resulted in a ‘no test’ and loss of the test asset [pit] as a result of test set up issues,” according to the NNSA report. Another destructive pit test scheduled for last year — after being delayed for at least a year — had to be abandoned outright because a nuclear safety analysis of the work wasn’t completed, the NNSA’s evaluation of the lab said.

Other plutonium work at PF-4 also has not fully resumed. At a public hearing in Santa Fe on June 7, the head of NNSA’s oversight office at Los Alamos said that federal permission in particular has not been granted for renewed work with plutonium liquids, which is needed to purify plutonium taken from older warheads for reuse, normally a routine practice.

Safety official McConnell also told the hearing that while Los Alamos is making progress, it still has been unable to resolve the safety issue that provoked its shutdown four years ago, namely an acute shortage of engineers who are trained in how to keep the plutonium from becoming “critical” and fissioning uncontrollably on its own because too much of it is concentrated in a particular space. “They’re not where we need them yet,” he said of the lab and its managers.

McConnell also disclosed that NNSA is now quietly studying whether to keep plutonium pit operations at Los Alamos. Options being considered include upgrading the facilities there or “adding capabilities or leveraging existing capabilities elsewhere in the country, at other sites where plutonium is already present or has been used.”

Active NNSA sites that fit that description include the Savannah River Site in South Carolina, the Pantex plant in Texas and the Nevada National Security Site. The NNSA expects to complete its analysis by late summer.

“The lab has struggled to hire experienced engineers,” the lab’s criticality safety chief said in the presentation to colleagues at Sandia last month. “We recognize and acknowledge that we are on a multi-year journey to eliminate resource constraints and to become completely compliant with national standards.”

A separate Defense Nuclear Facilities Safety Board report in February detailed the magnitude of the shortfall:

Los Alamos’ dangerous work, it said, demands 27 fully qualified criticality safety engineers.

The lab has 10.